Introducción

Currently, it is possible to observe diverse environmental problems around us, such as deforestation, which is carried out for multiple purposes, primarily for paper manufacture. For centuries humans have used fibrous raw material to make paper. (Area, 2008). The paper and related products are made from cellulose, the main component of plant cell walls. This cellulose can come from various plants, such as cotton, wood, cereal straw, and sugar cane, among others (Area, 2008), although most papers are made from cellulose from wood (Lera Santín, 2011).

Trees are of major environmental importance since they host many species (birds, insects, mammals); in addition to photosynthesis, providing oxygen, and absorbing carbon dioxide. Furthermore, they help regulate the planet's climate and prevent soil erosion. Deforestation is a severe problem and one of the leading causes of habitat destruction, causing biodiversity loss, and negative changes in carbon dioxide (CO2) fixation. In deforesting regions, the soil is affected by erosion and is frequently degraded to non-productive lands. Considering all these negative environmental impacts, there is a promising solution, which consists of using bacterial cellulose obtained from microorganisms. Bacterial cellulose, like plant cellulose, is an insoluble extracellular polymer that is produced by a variety of bacterial species within the genera Achromobacter, Agrobacterium, Rhizobium, Sarcina, Zoogloea, and Gluconacetobacter (Chávez-Pacheco et al., 2004). Gluconacetobacter xylinus (formerly Acetobacter xylinum) is a Gram-negative bacterium, strictly aerobic, that performs incomplete oxidation of several sugars and alcohols (a process known as oxidative fermentation). Its natural ecological niche is decomposing fruits and vegetables, and it can produce bacterial cellulose on liquid and solid media by forming a film on the surface (Chávez-Pacheco et al., 2004). The cellulose synthesized by G. xylinus is structurally and chemically the same as the plant cellulose; however, the bacterial cellulose is found with high purity, free of lignin and hemicellulose, and has a high capacity for water absorption and mechanical resistance. Cellulose fibers synthesized by bacterial cellulose are much smaller than wood fibers (Chávez-Pacheco et al., 2004). These peculiarities make bacterial cellulose a feasible material for papermaking.

Conventional paper manufacturing

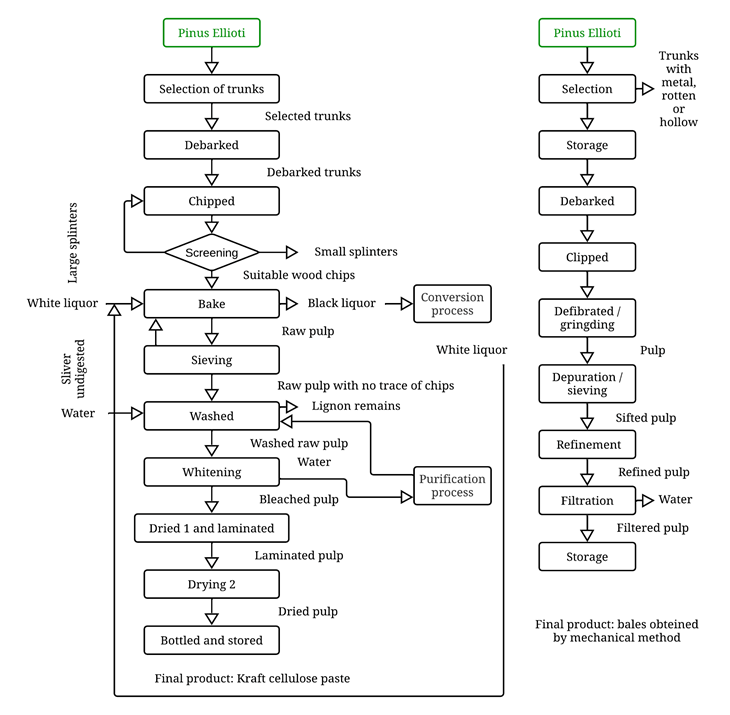

In papermaking there are multiple production methods, previously the most popular was mechanical abrasion and the application of chemicals based on caustic soda, sulfites, and sulfates. Currently, the most widely used methods are the mechanical and the Kraft method (based on sodium hydroxide and sodium sulfide) (Boeykens, 2006; Mues et al., 2018).

The paper-making process begins with the treatment of raw material by debarking and shredding the wood to obtain the cellulose. Then, the pulp is prepared, depending on the type of tree it came from: i) chemical treatment in which the wood previously converted into small chips is passed through a cooking process with chemical products, for example, the kraft treatment for resinous trees of Evergreen, currently one of the most used (Boeykens, 2006), covering approximately 72% of the world's cellulose production, this process generates a large amount of waste that is difficult to biodegrade and has use of 60% (Mues et al., 2018); and ii) mechanical process for trees of expired leaf, this method represents 20% of world production, which requires significant energy consumption and its use is 90 to 98% to obtain pulp (Mues et al., 2018). The composition of the wood is complex. Cellulose is the cell wall's basic structural element and is accompanied by lignin and hemicellulose.. It gives it a dark brown coloration, for that reason, it requires a bleaching process. In this stage can be used different bleaching agents like hydrogen peroxide (which changes the structure of lignin altering the color, but does not eliminate it), chlorine, hypochlorite, or chlorine dioxide, which generates toxic waste, in addition, the treatment of water after bleaching (Boeykens, 2006; Mues et al., 2018; Merizalde et al., 2019). At this point the cellulose pulp has high water content, so it is deposited in a machine where it is transferred on a long belt driven by rollers, then, the water is removed by different procedures, like gravity, vacuum, pressure, and drying. And finally, a massive sheet of paper is obtained, which is rolled up to form a bovine (Figure 1) (Mues et al., 2018).

Challenges in conventional paper manufacturing

In modern life, new launches and innovations are commonly observed; however, something as old and essential as paper cannot be dispensed with for cultural industry and transfer of the information.. According to Domínguez Ríos et al., (2017) "The paper industry is at the top of the ranking in terms of use of natural resources and generation of pollutants, all to manufacture a product that is usually immediately discarded". Despite all the technological advances and automation, the paper role has not been entirely replaced, and it continues to be essential for different areas. Adding that the good quality, low cost, and accessibility that the public has within reach and at home is thanks to inkjet printers because the consumption and demand for paper are constantly increasing (Domínguez Ríos et al., 2017).

On the other hand, the immoderate manufacture and consumption of paper have a strong environmental and social impact on the planet. To produce the paper, the use of plant cellulose, which constitutes the cell membrane of the plants, is necessary. The paper industries cut down millions of trees to obtain the plant cellulose, which is cause for concern since the forests are being destroyed or transformed into plantations.

Seventeen percent of the fiber used comes from primary forests, 54% from secondary forests, and, lastly, 29% from forest plantations (Greenpeace, 2004). Another problem in papermaking is that starting from the wood, the fibers are first separated by grinding the wood, or by dissolving the lignin with heat and chemicals for bleaching (Table 1). This cellulose is mixed with water and this mixture goes to the paper machine. Then, the water is removed by various procedures and finally, the paper is obtained, thus generating wastewater that can be treated in certain processes, but at the end of the process, effluents are obtained that still contain toxic agents (Mues et al., 2018; Merizalde et al., 2019; Cerda et al., 2019).

Table 1. Bleaching agents for papermaking (Teschke & Demers, 2001).

| Agents | The concentration of the agent (%) | pH | Consistency (%) | Temperature (°C) | Time (h) |

|---|---|---|---|---|---|

| Chlorine | 2.5-8 | 2 | 3 | 20-60 | 0.5-1.5 |

| Sodium hydroxide (NaOH) | 1.5-4.2 | 11 | 10-12 | <80 | 1-2 |

| Chlorine dioxide (ClO 2 ) | 1 | 0-6 | 10-12 | 60-75 | 2-5 |

| Sodium hypochlorite (NaOCl) | 1-2 | 9-11 | 10-12 | 30-50 | 0.5-3 |

| Oxygen (O 2) | 1.2-1.9 | 7-8 | 25-33 | 90-130 | 0.3-1 |

| Hydrogen Peroxide (H 2 O 2 ) | 0.25 | 10 | 12 | 35-80 | 4 |

| Ozone (O 3 ) | 0.5-3.5 | 2-3 | 35-55 | 20-40 | <0.1 |

| Sulfur dioxide (SO 2 ) | 4-6 | 1.8-5 | 1.5 | 30-50 | 0.25 |

| Sodium dithiosulfure (NaS 2 O 4 ) | 1-2 | 5.5-8 | 4-8 | 60-65 | 1-2 |

Environmental impacts of conventional paper manufacturing

The production of paper generates two types of environmental impacts, such as i) the depletion of natural resources, mainly due to the felling of trees, secondary forests, or forest plantations where a certain area is usually deforested to plant different types of trees.In Mexico, it is estimated a loss of 26 thousand hectares of forests, of which 182 million trees are cut down. The main reason occurs due to the irresponsible consumption of paper, however, worldwide the Per Capita consumption of paper is 55 Kg per person in a year (Haggith &Martin, 2018). Moreover ii) the degradation of the environment due to the use of chemicals in the manufacturing process, which can be solid, liquid and gaseous pollutants (Baird & Cann, 2018).

Paper manufacturing is considered highly polluting due to the use of chemicals in the pulping and bleaching process of the raw material. As described above, in this process, it is necessary to remove lignin from wood chips. The discharged water effluents can contain significant amounts of toxic substances, which can cause the death of living organisms and negatively affect terrestrial ecosystems (Bajpai, 2017). Wastewater generated in the wood preparation phase includes mainly solid organic matter - bark, branches, dirt, sand, etc. - and dissolved as the wood is chipped and washed. Wastewater is usually brown and contains mainly wood debris, soluble material, and chemicals; the brown color is mainly formed by phenolic derivatives of lignin, which arise from the depolymerization of lignin. The wastewater produced in the bleaching process is generally of no greater strength than the wastewater discharged in the pulping process, but toxicity is more problematic.

If molecular chlorine or chlorine dioxide is used in the bleaching process, chlorinated organic substances such as chlorophenols, dioxins, resin, fatty acids, and furans can be produced. Most of these are highly toxic, bioaccumulative, and mutagenic. Inorganic chlorate-containing compounds are also formed when chlorine in any form is used in the bleaching process. They are salts of chloric acid and contain chlorate ions. Chlorates are strong oxidizers and often react readily with organic materials present in wastewater. Wastewater from paper machines will contain high concentrations of suspended solids, biological oxygen demand, chemical oxygen demand, and inorganic dyes as a pigment, binder, and fibers are lost in the effluents (Bajpai, 2017). Soil also plays a crucial role in the hydrological cycle. The water stored in the soil (green water), accounts for about 90% of the water consumed by crops worldwide. This service and the soil's capacity to absorb and emit heat make it a vital climate regulator. (Secretaría de Medio Ambiente y Recursos Naturales (SEMARNAT), 2016). The loss of soil quality sedimentation of lakes and rivers, reduced associated with deforestation processes causes environmental problems such as erosion, catchment water and aquifer recharge, flooding, gradual loss of soil fertility, decreased productivity, and negative impacts on biodiversity (Liu et al., 2018a), in addition, the paper industry uses approximately 4% of energy, which is why it is considered to have higher energy consumption, for this reason in (Table 2), you can see the amount required for energy consumption and water for papermaking.

Table 2. Water and energy consumption required to manufacture paper (Rojas Pérez et al., 2020).

| Raw material | 1-ton paper | 500 virgin fiber foils | Recycled paper |

|---|---|---|---|

| Water | 150,000 a 200,000 L | 130. 6 L | 2,000 L |

| Energy | 7.000 kW/ h | 26,8 kW/h | 2 750 kW/h |

Impacts on human health from conventional papermaking

Sulfur compounds are formed in the kraft process, which covers 72% of the world's pulp production, are discharged into the atmosphere. This chemical process separates the cellulose fibers through an alkaline process that generates the dissolution of lignin. (Herrera & Amurrio, 2021). Another impact on health is the use of chlorine since, a polluting agent, it is also a cause of diseases in employees and in some communities close to paper manufacturing plants (Ferro et al., 2019).

A case study in Mexico City, entitled "Occupational health in a paper company in the State of Mexico", written by Valdovinos & Franco (2016), aimed to assess the situation of safety, hygiene, ecology, civil protection, and health services of workers in a paper company located in the State of Mexico. The Proverifica model was used, which allowed the reconstruction of the main work process: production. The health of workers is significant risk since the paper industry is considered one of the riskiest industries for the welfare of employees, as several studies have shown the health damage that can occur: hearing loss, increased risk of heart disease, lung disease, increased development of certain types of cancer; in this study, due to the lack of control measures, the risk of hearing damage in workers is up to eight times more than in those who work in a controlled noise environment. Within the paper industry, there are at least eleven chemical substances that are considered to be cancer-producing agents. This can be related to the increase in mortality from lung cancer after exposure to sulfur dioxide, to the development of non-Hodgkin's lymphoma and leukemia due to contact with sulfur dioxide 4-7; which causes premature deaths associated with pulmonary and cardiovascular diseases. In addition, it has been found that ovarian cancer incidence rates correlate with exposure to chemicals during paper manufacturing. It was concluded that the company has deficiencies in its occupational health systems and programs, mainly due to the lack of involvement of management levels. This situation can be improved by establishing plans and policies related to occupational health; implementing a methodology for risk detection and control, and applying preventive programs for occupational accidents and diseases.

Plant cellulose

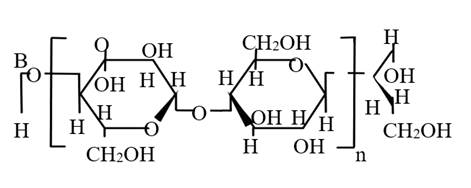

Cellulose is the main component of the cell wall of plants and is associated with lignin, hemicellulose, and other components of wood (Curilla Paucar & Diaz Huamani, 2020). The plant cellulose is a linear polymer whose structure (Figure 2) is formed only by units of β-D-glucose, which is linked successively between carbon atom 1 of β - D - glucose and atom 4 of the following glucose molecule, thus forming cellobiose molecules (β-D-glucose disaccharide) (Area, 2008).

Figure 2. The structure of cellulose. The repeating unit is known as cellobiose (Area, 2008).The chemical formula of cellulose is (C6H10O5)n where "n" represents the degree of polymerization (number of units that are repeated) (Area, 2008).

The cellulose has a degree of polymerization between 13000 and 14000 (Table 3); however; the dimensions of microfibrils and the degree of polymerization vary depending on where the cellulose comes from. The degree of polymerization may vary from 15,000 units for some cotton fibers, 10,000 for native wood cellulose (Area, 2008), to values near 50 units for some microcrystalline cellulose (Santos de Dios, 2015).

The cellulose molecules tend to form intramolecular and intermolecular hydrogen bonds; these bonds greatly affect on the morphology, structure rigidity, orientation, resistance, and reactivity that cellulose chains present (Area, 2008). The intermolecular hydrogen bonds allow a tertiary fibrillar structure of high crystallinity (Area, 2008). The cellulose has two types of regions: i) crystal regions where the ordering is high, they are more stable and difficult to penetrate by solvents or reagents, and ii) amorphous regions where the order is low, they are easily penetrated and consequently more susceptible to hydrolysis reactions (Area, 2008). The cellulose may form 6 different crystal structures of which cellulose I and cellulose II are found in nature, and from these, it is possible to obtain the others by heat or treatment with chemical agents (Carreño Pineda et al., 2012).

Some properties and characteristics of plant cellulose (Table 3) are that plant cellulose can be found in high purity. And the fiber width covers around 1.4-4.0x10-2 mm or what is equivalent to 200 -300 MPa. According to Chávez-Pacheco et al., 2004 the water content and crystallinity are around 65% (60 and 56-65% respectively). Finally, it is metabolically inert and is not toxic or harmful (Area, 2008.).

Bacterial cellulose

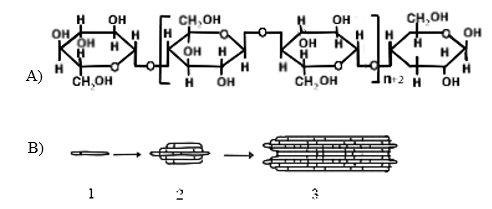

Like plant cellulose, bacterial cellulose is a polymer of glucose residues that are linked by a covalent bond between carbon 1 and 4 (β1-4) (Figure 3). Thus, linear chains are related (crystallized) by bonds of hydrogen and Van der Waals forces (Gorgieva & Trček, 2019). This cellulose is synthesized by species within the genera Achromobacter, Agrobacterium, Rhizobium, Sarcina, Zoogloea, and Gluconacetobacter (Chávez-Pacheco et al., 2004). Among them, the one possessing the best efficiency to produce cellulose, and for that reason, the most studied is Gluconacetobacter xylinus (Pecoraro et al., 2007). The bacterial cellulose is identical to that produced by plants regarding its molecular formula, however, its morphology and physical properties are different (Table 3) (Carreño Pineda et al., 2012). The structure (microfibrils) is formed by the grouping of at least 10 cellulose chains (Figure 3) (Gorgieva & Trček, 2019). Two characteristics are particular to bacterial cellulose microfibrils: their polarity is unidirectional, and they are of variable thickness.

Figure 3. Bacterial cellulose is stable in basic solutions but is susceptible to alkaline hydrolysis under drastic conditions (1M NaOH, 170 ° C), various oxidizing agents may affect their properties by breaking the chains and altering the structure. A) Molecular structure of bacterial cellulose; B) Microstructures of CB; 1. Linear chain; 2. Microfibril; 3. Microfibril bundle. Adapted from Chávez-Pacheco et al. (2004).

Among the unique characteristics of bacterial cellulose is its high degree of crystallinity (greater than 60%) (Table 3). Thus, due to its crystallinity, bacterial cellulose has excellent mechanical properties, high resistance to pressure, elasticity, and durability, as well as a high capacity for water absorption. In addition, bacterial cellulose to these industrially important physicochemical properties since it is metabolically inert, non-toxic, does not cause an allergic reaction to contact (Chávez-Pacheco et al., 2004), biocompatible and biodegradable, and has a greater surface area than that found in wood pulp. Table 3 shows the difference in some properties and characteristics between plant and bacterial cellulose. One of the most important characteristics is its purity, therefore it is free of lignin and hemicelluloses (Carreño Pineda et al., 2012).

Bacterial cellulose is an alternative to plant cellulose for the paper industry

The bacterial cellulose is considered to have a composition suitable for papermaking; because it complies with the chemical aspects of plant cellulose, but also with unique physical properties (Barrera-Martinez et al., 2021) such as its purity (free of lignin, hemicelluloses, and other components of wood); which allows decreased extraction and purification costs concerning cellulose of plant origin (Perna, 2013) since lignin is the undesirable component of wood for the paper industries because it is a hydrophobic material, therefore its presence in pulps inhibits water absorption, fiber waves and refining difficulty (Francés Gómez,2022). Thus, no other component can interfere with the pulp or recovery processes due to its purity,. Furthermore, its high degree of polymerization and covalent bonds allow the fibers to fit together, to produce a uniform sheet of paper. It also has excellent mechanical properties, high-pressure resistance, elasticity, and durability, a high capacity to absorb water, and a larger surface area than wood cellulose (Barrera-Martinez et al., 2021). These particularities make bacterial cellulose a possible material for papermaking.

Table 3. Difference between bacterial and plant cellulose. (1) Chávez-Pacheco et al. (2004). (2) Pecoraro et al., 2007. (3)(Area, 2008).

| Properties | Plant cellulose | Bacterial Cellulose | |

|---|---|---|---|

| Composition % (1) | Cellulose | 43-47 (1) | 98 (1) |

| Lignin | 16-24 (1) | 0 (1) | |

| Hemicellulose | 23-35 (1) | 0 (1) | |

| Extract | 2-8 (1) | 0 (1) | |

| Degree of polymerization | 13,000-14,000 (2) | 2,000-6,000 (2) | |

| Fiber width | 1.4-4.0 X10 −2 mm (2) 200-300 MPa | 70-80 nm (2) | |

| Water content % | 60 (2) | 98.5 (2) | |

| Crystallinity % | 56-65 (2) | 65-79 (2) | |

| Young’s modulus | 5.5-12.6 GPa (2) | 15-30 GPa (2) | |

| Toxicity | 0 (3) | 0 (1) | |

Gluconacetobacterxylinus for production of bacterial cellulose.

Gluconacetobacter xylinus was selected (previously Acetobacter xylinum) because of its highest cellulose-producing capacity (Barrera-Martinez et al., 2021), compared to other genera such as Achromobacter, Agrobacterium, Rhizobium. Table 4 shows the incompatibility in the cellulose structure of the previously mentioned genera that are suitable for the production of polymers.

Table 4. Cellulose structure differences between bacterial genera (Guinea Nava, 2016).

| Genera | Cellulose structure |

|---|---|

| Acetobacter | An extracellular film composed of tapes |

| Achromobacter | Fibrils |

| Aerobacter | Fibrils |

| Agrobacterium | Short fibrils |

| Alcaligenes | Fibrils |

| Pseudomonas | Non-distinguishable fibrils |

| Rhizobium | Short fibrils |

| Sarcina | Amorphous cellulose |

| Zoogloea | Not well defined |

G. xylinus, unlike other biological systems, is capable of fabricating cellulose in sufficient amounts, which it performs in the form of fibrillar extracellularly. A single G. xylinus bacterium is capable of polymerizing 200,000 glucose molecules per second into β-1-4 glucan chains (Perna, 2013). G. xylinus is a non-pathogenic mesophyll belonging initially to the genus Acetobacter identified by A. J. Brown in 1886, due to its ability to produce cellulose (Costa et al., 2017), is found in the soil, its natural habitat is fruits and vegetables in decomposition. It can produce bacterial cellulose on liquid and solid media (Chávez-Pacheco et al., 2004) from a wide range of carbon and nitrogen sources (Liu et al., 2018a). The yeast extract is the most widely used nitrogen source for its growth. The peptone, polypeptone, tryptone, corn liquor, and ammonium sulfate are also used in this species production of bacterial cellulose (Chávez-Pacheco et al., 2004). G. xylinus growth conditions are at pH 5 and 6, the temperature of 28-30 ° C in a complex medium consisting mainly of glucose, and the composition of the culture medium is variable according to the strain used in the system (Chávez-Pacheco et al., 2004).

G. xylinus synthesizes bacterial cellulose through two important metabolic pathways: i) the Pentose phosphate cycle (carbohydrate oxidant) and ii) the Krebs cycle (oxidizing organic acids). The glycolysis does not participate in the synthesis of bacterial cellulose in G. xylinus due to the lack of the enzyme phosphofructokinase 1 (Liu et al., 2018b), which is responsible for the conversion of fructose-6-phosphate to fructose-1,6-bisphosphate. The bacterium can produce de novo glucose from substrates such as glycerol, citrate, and other Krebs cycle intermediates by gluconeogenesis, and can convert hexose phosphate (fructose and mannose) into glucose-6-phosphate, for the synthesis of polysaccharides (Liu et al., 2018).

The biosynthesis process (Figure 4) starts with the entry of the substrate into the bacterial cell and its conversion to glucose-6-phosphate by the enzyme glucokinase; subsequently, glucose-6-phosphate passes to glucose-1-phosphate due to the action of the enzyme phosphoglucomutase, after glucose-1-phosphate is converted to UDP-glucose in the presence of the enzyme UDPG pyrophosphorylase; finally, due to the action of the cellulose synthase enzyme, which is responsible for polymerizing glucose, cellulose is formed (Carreño Pineda, et al., 2012).

Figure 4 The bacterial cellulose biosynthesis process. CS: cellulose synthase; PGM: phosphoglucomutase; PMU: uridine-diphosphate (Guinea Nava, 2016).

On the inner membrane is located the cellulose synthase enzyme complex (Perna, 2013). The operon of cellulose synthase (bcs) consists of four genes that are transcribed as a polycistronic mRNA, each gene encoding a protein (A, B, C, and D) required for bacterial cellulose biosynthesis (Liu et al., 2018b) (Figure 5). The bcsA gene catalyzes the polymerization of cellulose from UDP-glucose (Schmid et al., 2015). In addition, the bcsA gene contains a Pilz domain at its c-terminal end. The bcsB gene is found in the periplasm, bcsB interacts with bcsA through its C-terminal transmembrane helix and regulates bacterial cellulose synthesis by interacting with cyclic diguanylate (c-di-GMP) (Liu et al., 2018b); this reaction of cyclic diguanylate (c-di-GMP) to pilz at the c-terminal end is anchored to the inner membrane and allows the polysaccharide to be transported through the periplasmic space (Prada Ramírez, 2014).

Figure 5. Cellulose formation and its excretion into the culture medium through the cell membrane of the microorganism G. xylinus thanks to the function of the cellulose synthase operon. Adapted from Carreño et al (2012). (A) Bacterial cellulose biosynthesis and extrusion process. (B) Operon of the cellulose synthase enzyme complex (bcs). Adapted from Schmid et al. (2015)

Table 5. Differences between static media and shaken media.

| Static media | • Inoculation of 1-14 days. • Temperature 28-30 °C. • pH less than 7 • It forms on the surface of the crop. • Lower CB production. • Low production cost |

| Shaken media | • High cost of production. • Higher concentration of oxygen. • Increased CB production. • Shape of irregular cumulus. |

The function of the bcsC gene and the bcsD gene has not yet been discovered. However, it is proposed that the bcsC gene functions as a 3.5 nm pore-forming protein, which is diametrically aligned in the cell membrane to allow cellulose secretion. In contrast, the bcsD gene appears to be involved in controlling the crystallization process of cellulose nanofibrils (Liu et al., 2018b). Besides, it is hypothesized that the bcsD gene is found extracellularly and that its function is to twist the newly synthesized cellulose fibrils, generating higher-order fibers, which would explain why G. xylinus produces fibrillar cellulose and other bacteria that lack the bcsD gene produce amorphous cellulose (Prada Ramírez, 2014).

Recently, Kubiak et al., (2014) identified the orf2 whose function is still unknown, and the bcsZ gene that encodes an endo-β-(1-4)-glucanase whose function is to divide the bacterial cellulose chains, consequently, more chains are generated and when these are joined microfibrils are formed. Finally, located downstream (3') of the cellulose synthase operon there is a gene that encodes a β-glucosidase, which hydrolyzes glucose units formed by more than three monomers and plays an important role in cellulose production and the microfibril packaging produces the cellulose fibers and ribbons (Figure 4) (Schmid et al., 2015) which reach a thickness of 1 to 9 µm and form an extensive reticulated structure stabilized by hydrogen bonds, the condensation of the tapes gives rise to the three-dimensional structure or macrostructure of the bacterial cellulose (Gorgieva & Trček ,2019).

Production of bacterial cellulose

The production of bacterial cellulose strictly depends on the growth medium, which can be static or agitated. Furthermore, it influences the sources of carbon, nitrogen, pH, temperature, availability of oxygen, minerals, the proportion of the inoculant, and finally the age that the inoculum present (Santos et al., 2016; Aswini et al., 2020). In the CB production industry, it is common to use molasses obtained from sugar cane as a carbon source. In addition, different additives are used to increase its production (Table 5). These additives can be glycerol, sodium alginate, ethanol, etc. among others (Gorgieva & Trĉek, 2019).

Currently, there are different methods to produce bacterial cellulose, some of them can be obtained through shaken, static cultures or grown in bioreactors (Wang et al., 2019). When static media are used, there is usually a uniform cellulose layer i.e., a film is formed between the liquid and air phase of the culture, the purpose of cellulose synthesis is to supply a firm surface matrix, which allows the microorganism, a strictly aerobic, to be close to the gas phase (Carreño Pineda et al., 2012); in the case of shaken cultures or agitation, cellulose usually appears in the form of clusters or masses in an irregular manner (Tuya Salas et al., 2021). The production of bacterial cellulose through the use of agitated cultures is more advisable for the industry since a greater production is obtained (due to greater availability of oxygen), however, this technique usually presents a low level of polymerization and has a higher crystallization characteristic when compared to static culture (Lahiri et al., 2021; Gorgieva & Trĉek, 2019).

Reactors used in the production of bacterial cellulose

As mentioned, bacterial cellulose can be produced by a) bioreactors called airlift and b) trickling bed.The first (a) presentssufficient oxygen with a reduced feed source, resulting in cellulose in pelletized form. The second (b) has a high availability of oxygen but at a decreased shear strength, where the product can be found in irregular leaves (Gorgieva & Trĉek, 2019).On the other hand, there is a so-called rotating disk reactor, which consists of a series of circular disks mounted on the horizontal axis that rotate and are alternately exposed to the fermentation environment and the air. The cellulose obtained in the reactor does not face strong shear stress and has excellent oxygen transmissibility, so microorganisms can easily come into contact with it. Thus, the production of bacterial cellulose by Gluconacetobacter xylinus was maximized at 5.52 g/L; In addition, constant aeration improve production, reaching a production of 5.67 g/L (Guinea Nava, 2016).

Valuation of trees, water pollution, and soil los

Carbon dioxide (CO2) is the primary anthropogenic greenhouse gas (GHG) in the atmosphere, it contributes approximately 65% to the radiative forcing produced by long-lived GHGs (National Oceanic and Atmospheric Administration (NOAA), 2016).

Of the total emissions from human activities during the period 2006-2015, about 44% were stored in the atmosphere, 26% in the oceans, and 30% on land. One way to reduce the effects of CO2 is to store it in the biomass through photosynthesis, considering that the potential for carbon capture by plant communities varies according to their structure and the constitution of each ecosystem (Jiménez Pérez et al., 2020)

Since the end of the of the last century, Central American countries carbon fixation and capture capacity have been evaluated to measure their potential for the mitigation of Greenhouse Gases (GHG) caused by growing industrial activity (López et al. 2018). Forest plantations have become a strategic means of fixing atmospheric CO2 in the plant structure. In the paper industry, the prices of a ton of fixed C vary between $ 4.6 - 50.4 US, depending on the actual discount rates and the amount of C added to that obtained in the traditional wood business (Gutiérrez Velez & Lopera Arango, 2001).

The absorption potential of the forestry sector in Mexico has been estimated at 58 million tons of carbon dioxide equivalent (t CO2e) by 2020 and 96 million tons of CO2e by 2030 (Coordinación General de Producción y Productividad de la Comisión Nacional Forestal (CONAFORT), 2013). For Mexico, in 2014, 137.8 million hectares of forest area were counted, representing 70.5% of the 196.5 million hectares of the national territory. México wood production is insufficient to satisfy the internal demand. In 2016, 6.71 million m3 of round wood was produced (29% of the total volume), with an apparent consumption of 23.4 million m3. Of the 6.71 million m3 of wood, different classes of wood products were obtained where cellulose represents a total of 0.61 million m3 (9.2%); however, from 1997 to 2016, a decreasing trend of cellulose was registered with an average annual rate of -3.50% (Centro de Estudios para el Desarrollo Rural Sustentable y la Soberanía Alimentaria (CEDRSSA), 2019). Even so, a representative amount of the country's forest area continues to be deforested, with 9.2% going to the production of this cellulose.

20% of the wood used in papermaking comes from original natural forests and 29% from plantations, and 54% from secondary forest (Greenpeace, 2004). Plantation forests are increasing rapidly in the world to alleviate deforestation and degradation of natural forests, along with providing goods and services. Monoculture plantations have been the dominant type of plantation in practice and are well-recorded in research, a higher diversity of tree species increases the number of ecological niches, which can further increase the number of associated species, loss of soil productivity and fertility, disruption of hydrological cycles, risks associated with plantation forestry practices (e.g., the introduction of exotic species), risks of promoting pests and diseases, higher risks of adverse effects of storms and fire, and negative impacts on biodiversity (Liu et al., 2018b).

In the paper industry, in addition to the problem of deforestation, there is high consumption of water, energy, and chemical substances that can lead to the contamination of water sources and air (Romero Conrado et al., 2017). Water is one of the key components of papermaking; paper production is unthinkable without water. The pulp and paper industry is ranked as the world’s third-largest water consumer and produces high amounts of wastewater. In 2019, the total use of water in Spanish pulp and paper mills stood at 111 million m3 per year, which is half the water of water than in 1990 and 30% less than in 2000, while production has increased by 60% since the beginning of the nineties and 22% since the beginning of the XXI century (Carpintero, 2019). It is worth mentioning that the paper industry has improved its processes in the last few decades and as a result, has been able to reduce its water consumption significantly. For the last several years the paper industry has been working to reduce its freshwater consumption and its wastewater output. Reuse is an important approach for reducing wastewater generation and consumption of wastewater, however, the process is still carried out mainly from water from rivers 69%, from wells 19% and only from the network, and recovered water 12% (Carpintero, 2019).

Thanks to the voluntary agreement signed between the Ministry of the Environment and the Association of Pulp and Cardboard Manufacturers (ASPAPEL) during the years 2000-2009, marked a fundamental milestone in the efficiency of water use and discharges in the sector, achieving a 37% reduction in the use of water per ton produced (from 24.5 m3/t to 15.5 m3/t) and a 28% reduction in the use of total water (going from 160 cubic hectometers/year to 115 cubic hectometers/year), despite an increase in production of 14% in the same period. To reduce water consumption, the Spanish paper industry requires a powerful investment effort (almost 1,400 million euros of investment in the last four years alone), to reduce environment effects(Carpintero, 2019).

The importance of soil losses can be focused on the services it provides, like “filtering of nutrients and contaminants”, the economic cost numbers based on estimations of nitrate unit damage, based on the soil retention and the unit damage cost, were in the range 0-280 id$ ha-1 year-1. For the service of “climate regulation” the total average cost of reducing greenhouse gas emissions under the Mitigation Scenarios is estimated at between €190 and €240 tons of CO2 (2008 prices), and for “biomass production” the grassland, shrubland, and pasture cost 740 id$ha-1 year-1 (270-1580); non-irrigated arable land 2230 id$ha-1 year-1 (440-4730); fruit and berry plantations cost 7500 id$ha-1 year-1 (6100-7580); and Olive groves 10,810 id$ha-1 year-1 (6540-10,910) (Jónsson et al., 2017). Soil can have or provide other important goods and services, maintenance is, therefore, essential to achieve environmental and economic sustainability.

Comparison of paper production costs with plant cellulose vs. bacterial cellulose

Bacterial cellulose represents the purest form of cellulose, and it possesses several unique properties. Despite its impressive potential for a wide range of commercial applications, bacterial cellulose is prohibitively expensive to manufacture. This high cost limits its use as an alternative to plant cellulose. The synthetic media commonly used for this kind of cellulose production are the major factor contributing to its high production cost. Therefore, efforts have been made to devise strategies for the effective and inexpensive production of bacterial cellulose, these include testing various waste materials such as fruit juices, industrial wastes, and food wastes (Islam et al., 2017). The cost of the carbon source plays a key role in bacterial cellulose production costs. Low-cost carbon sources such as glycerol must be obtained as a byproduct of biodiesel production, and grape bagasse from regional wine production for example. The volumetric productions (g/l) and the yield (g/g) of bacterial cellulose in a culture medium by replacing glucose with other carbon sources show that the production of this type of cellulose with glucose has a cost of 0.22-0.24 U$D/kg, the cane molasses of 0.12 U$D/kg, commercial glycerol 0.46-0.75 U$D/kg and glycerol from biodiesel 0.04-0.15 U$D/kg (Vázquez et al., 2013).

In Latin America with a volume produced of 6,152 thousand tons of cellulose, there are profits of 1,486 million dollars. Between 2002 and early 2008, the price of pulp increased from $350 to $755 per ton, an increase of 116%. From the second semester of 2008, the price of cellulose started to fall, reaching 475 dollars at the beginning of 2009, that is, a fall of 37% (Chapela, 2012).

Conclusions

Papermaking has caused several negative impacts on the environment derived from deforestation, such as habitat loss, biodiversity, soil erosion, and reduction of carbon dioxide (CO2) fixation, thus suggesting the need to develop sustainable alternatives to counteract these impacts, one of these alternatives is bacterial cellulose.

Gluconacetobacter xylinus has great similarities with plant cellulose (used for papermaking). It has been determined that bacterial cellulose is structurally and chemically equal to plant cellulose, however, it has better characteristics (high purity, high water absorption capacity and mechanical resistance, and high degree of polymerization) which makes it a feasible alternative for paper manufacturing, avoiding environmental damage caused by the processes of paper production, mainly deforestation, debarking, screening, and bleaching. Therefore, the knowledge of the growth conditions of G. xylinus, its metabolism, formation, and excretion of bacterial cellulose, and the structure of the synthesized cellulose, is decisive in knowing which reactor to use to achieve maximum production of bacterial cellulose.

Despite its great potential as an alternative to plant cellulose for papermaking, producing bacterial cellulose is expensive; however, we must measure what conventional paper manufacturing costs environmentally. Although the manufacture of paper with plant cellulose is indeed more economical, this leads to severe impacts on the environment. Therefore, it is considered necessary to continue making efforts to design strategies for the economical production of bacterial cellulose and to achieve sustainable paper manufacturing.

uBio

uBio